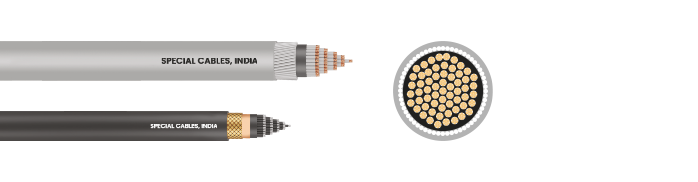

CONTROL CABLES

APPLICATIONS

Mainly used for interconnections for control circuits, communication systems, electrical panels, machine tools as well as lighting at lower loads.

TYPES & SIZES

Typically up to 61 cores from 1.0 sq.mm to 2.5 sq.mm with voltage grade up to 1.1 kV

Copper – Solid, Stranded (Circular) or Flexible – Bare or Tinned

PVC, PE, XLPE, LSZH, EPR

PVC, PE, Thermoplastic or Thermoset LSZH, Rubber, EVA

Galvanized Steel or Aluminium Round Wire / Flat Strip / Tape or GI / Tinned Copper Braid

Aluminium Mylar Tape with Copper Drain Wire, Copper Tape / Tinned Copper Braid

SPECIFICATION

Generally confirming to IS: 694, IS: 1554 (Pt-I), IS: 7098 (Pt-I), IEC: 60502-1, BS: 5467, BS: 6346, AS/NZS 5000.1 and designed to meet the customer’s requirements

Note

- The technical data provided is for stranded (Class 2) conductor and PVC. Details given are for reference only and may be revised without notice. Other details can be provided on request.

- Conductor D.C. Resistance at 20°C – Conductor Size: 1.5 sq.mm – 12.1 Ω/km (Bare), 12.2 Ω/km (Tinned) and 2.5 sq.mm – 7.41 Ω/km (Bare), 7.56 Ω/km (Tinned)

- The current ratings are given for Air Temperature @ 40°C, Ground/Duct Temperature @ 30°C, Thermal Resistivity of soil 1.5 km/W, Depth of laying 900 mm and may vary if the site conditions are different.

KEY FEATURES

- Cable design can be customised to meet customer requirements

- Provides high degree of protection against electrical interference

- Allows better transmission of power and signal at very low voltages to control processes and critical equipment with low effect of induced voltage.