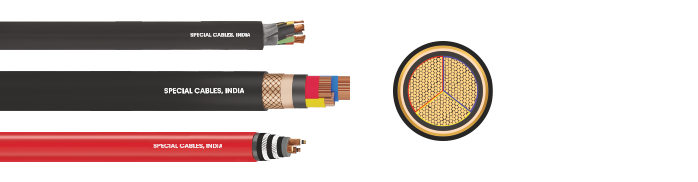

MINING CABLES

APPLICATIONS

Used across various mining operations in tunnelling, drilling, loading machines, pumps, etc. Subject to extremely harsh working conditions with extensive vibrations, impact and tension.

TYPES & SIZES

Single and Multi-cores starting from 1.5 sq.mm up to

630 sq.mm for voltage grade up to 3.3 kV

Aluminium – Stranded (Sector/Circular) or Copper – Stranded (Sector/Circular) or Flexible

PVC, XLPE, HEPR, LSZH, EPR

PVC, XLPE, LSZH, HDPE, Rubber-HR/HOFR

Single/Double Wire/Strip Armour along with Tinned Copper

to meet conductivity requirements of at least 50% of phase conductor. Tinned Copper Braiding can also be provided.

SPECIFICATION

Generally confirming to IS: 1554 (Pt-1 & 2), IS: 7098 (Pt-1 & 2),

IS -14994, IEC: 60502-1, BS: 5467, BS: 6346

KEY FEATURES

- Designed for long performance in harsh conditions

- High Flexibility, torsion & drag resistance

- Excellent abrasion and fire resistant properties