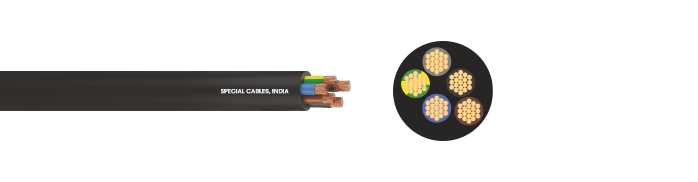

Rubber & Silicon Cables

APPLICATIONS

Used in a variety of industries, ranging from nuclear power stations, defence, windmills, mining, marine & offshore applications, railways, cranes and other heavy-duty equipment.

TYPES & SIZES

Single & Multi-core from 0.50 sq.mm to 630 sq.mm for voltage grade up to 3.3 kV (Unscreened)

Copper – Solid, Stranded (Circular) or Flexible – Bare or Tinned

Polyester Tape, Fibre Glass Tape or Rubberised Cotton Proof Tape, or any other tape of suitable material is applied over the conductor

Type IE1, IE2, IE3, IE4, IE5. For identification of cores, coloured insulation / numbered printing / numbered polyester tape / colour proofed RC tape is used

Type SE1, SE2, SE3, SE4,SE5, SE6

Galvanized Steel Wire / Flat Strip or GI/SS/ Tinned Copper Braid

SPECIFICATION

IS: 9968 (Pt-1), BS: 6500, BS: 7919, IEC: 60502-1

KEY FEATURES

- High performance in harsh conditions of heat and fire with better abrasion and weather resistance

- Excellent resistant to oils, gasoline, and certain chemicals enhances the performance of this wire in extreme environments.

- Better flexibility and low bending radius

- Wide range of operating temperature ranging from -55°C to 180°C

- Customisation options available to meet customer’s needs